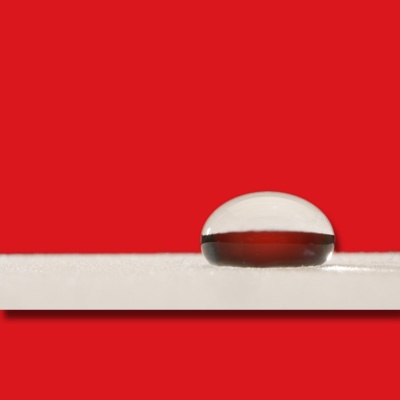

Cellular polymer materials are permeable to some degree, while other manufacturing materials like metals, glass, ceramics and dense loaded vinyls are not. To some, this porous quality may seem like a disadvantage. But that’s not true! Whether or not a material is right for your project comes down to your application.

How the Permeability of Polyurethane Foam Affects Sound Absorption

Topics: closed cell foam, open cell foam, Permeability

Top 4 Ways to Protect Your Product Designs Against Copycats

When developing a new product, there are a lot of hurdles to consider before bringing it to market. Before production starts, you should familiarize yourself with intellectual property (IP) protections in the U.S. and abroad.

Many businesses in the United States turn to locations overseas, like China, to produce goods, as it is usually more cost-effective in terms of labor. However, according to a 7-month investigation conducted in 2018 from the U.S. Trade Representative (USTR), “Chinese theft of American IP currently costs between $225 billion and $600 billion annually.”

Topics: Intellectual property theft, OEM, Product design, Copyright, Supplier

How to Design and Develop a 3D Molded Foam Solution

Developing a new product on the cutting edge requires innovative thinking. Original equipment manufacturers are continually trying to break the mold with their new product designs, but sometimes the end product doesn't work as intended.

Usually, manufacturers use flat foam barriers, foam absorbers, and damping pads to control temperature, noise, and heat emitted from machinery during operation. While 2D foam solutions can prevent a lot of energy management issues, 3D polyurethane molded foam solutions can provide additional benefits depending on the application.

But, how do you go from a 2D to 3D foam solution?

The Future of Composites in the Aerospace Industry

When it comes to determining how well an aircraft will perform, the thrust-to-weight ratio is one of the most important metrics. Aerospace manufacturers have always aimed to keep this ratio as low as possible by creating lighter aircraft, but the metals traditionally used in aircraft bodies are heavy. Composite materials, on the other hand, are lighter and enable manufacturers to create more fuel-efficient aircraft when mixed with metal. Let’s examine the history of composites in the aerospace industry and where future innovation is headed.

Topics: aerospace, composites

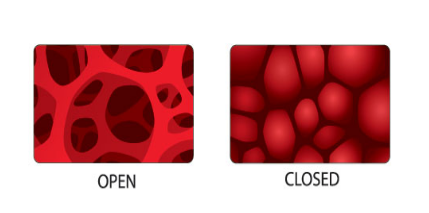

Open vs. Closed Cell Foam: Understanding Permeability

Porous plastic foam is on the cutting edge of insulation for heat, vapor, noise, and other elements. The two major variants of porous plastic foams are open and closed cell foams. Both types of foam are used in everyday products, but because of their structural differences, one type of foam may perform better than the other depending on the desired application.

Topics: closed cell foam, open cell foam

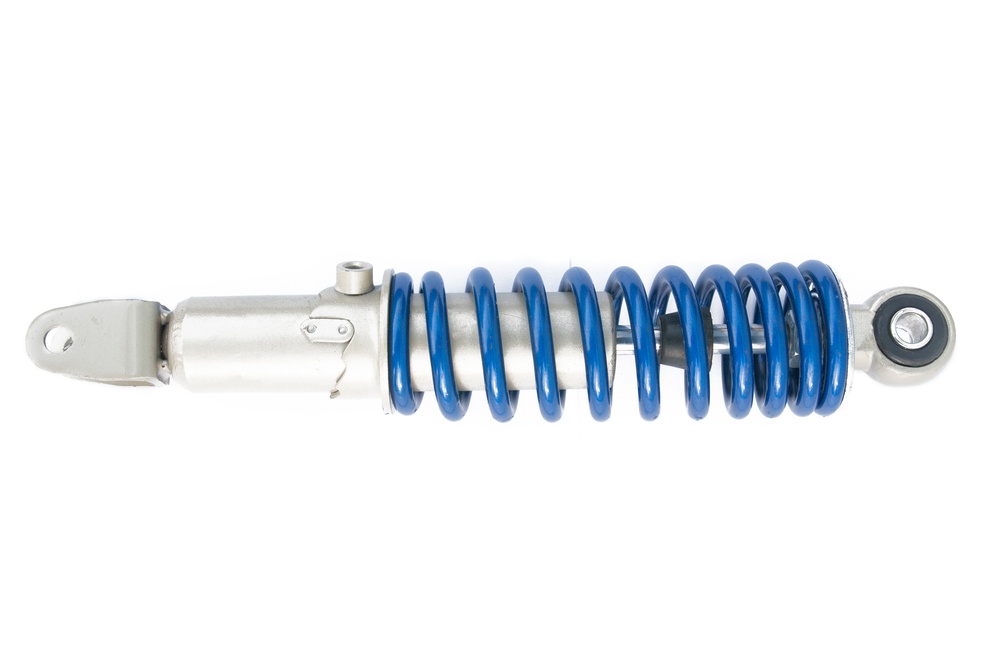

Advantages of ArmorFlex® and SquishyFlex® Anti-Vibration Mounts

Vibration isolation is an integral part of any engineering project and design. Experienced manufacturers know that stopping excessive vibration is necessary, or else it can cause wasted energy and damaged equipment, leading to broken products, expensive repairs, and reduced profits. Original equipment manufacturers need to be able to trust the reliability of the anti-vibration mounts they install or else they could wind up with subpar products and unhappy customers.

Topics: vibration isolation, anti-vibration mounts, ArmorFlex™, SquishyFlex™

Melamine Foam Insulation for Thermal Management, Noise Reduction, and Cost Savings

Melamine foam is an effective absorber suitable for applications involving noise control and thermal management. Polymer Technologies provides a range of melamine foam insulation for a variety of industries, mainly power generation, construction, rail transportation, heavy truck, aerospace, medical, and marine manufacturing. The foam is widely used because it is a versatile, flame resistant material that is lightweight, semi-rigid yet flexible, and easy to customize. This allows manufacturers to save production time and labor costs during installation.

Topics: Flammability, Insulation, vibration isolation, noise reduction

Keeping Up with the Demanding Trend of Machine Versatility

Engineers are always looking for more ways to implement new technologies in their machinery. Over the past decade, the drive to create more versatile machinery has only continued to increase. With the amount of power and technology being put into these machines, the need for greater insulation and noise reduction solutions has become apparent. When keeping up with the need to improve machinery, it's important to keep the health and safety of the operator in mind. There are a number of factors driving the trend for machine versatility. Here are 3 of the most significant:

Topics: product development

7 Questions a Polymer Supplier Can Answer During Product Development

When engineers are developing products that require a polymer solution—albeit rubber, insulation, or other material—deciding exactly which materials to use and finding a supplier is an integral part of the product development process. Performance of those materials is not the only concern, either: chances are you’re working within budget and time constraints and need to have expectations clearly defined. In addition to providing materials or a manufactured component, a good supplier is also your partner. Here are some questions you might have during the product development stage that an experienced supplier can address.

Topics: manufacturing, product development

Damping Techniques for Noise and Vibration Control

Damping is one of the most effective methods of controlling noise and vibration. It is a process that converts vibrational energy into heat, eliminating the vibrational energy through friction and other processes. Increasing damping or stiffness can both reduce resonant vibration and the resulting noise by preventing the vibration from travelling through the structure.

Topics: noise damping, noise and vibration